Design and Manufacturing of Specialized Tooling

At Accuma, we offer comprehensive services in the design and production of specialized tooling, which plays a crucial role in manufacturing processes requiring precise assembly, machining, testing, and quality control of components. Thanks to our expertise and access to cutting-edge technologies, we develop tooling tailored to the specific needs of our clients, optimizing production processes and ensuring the highest product quality.

Our specialized tooling solutions include:

Stamping dies and molds

Used for manufacturing components from metals, plastics, and composites,

Assembly tools

Custom fixtures, assembly stations, and precision positioning systems,

Functional test equipment

Tooling for mechanical, electrical, durability, and quality tests.

Inspection and measurement tools

Instruments for measuring dimensions, tolerances, positions, and angles, including optical and mechanical measuring systems.

During the design phase, we take into account:

Ergonomics

Ensuring user-friendly tooling that minimizes the risk of operator errors and accidents.

Material selection

Using high-quality materials such as tool steel, stainless steel, and wear-resistant composites to guarantee durability and reliability.

Precision and tolerances

Achieving micron-level accuracy for high process repeatability and superior product quality.

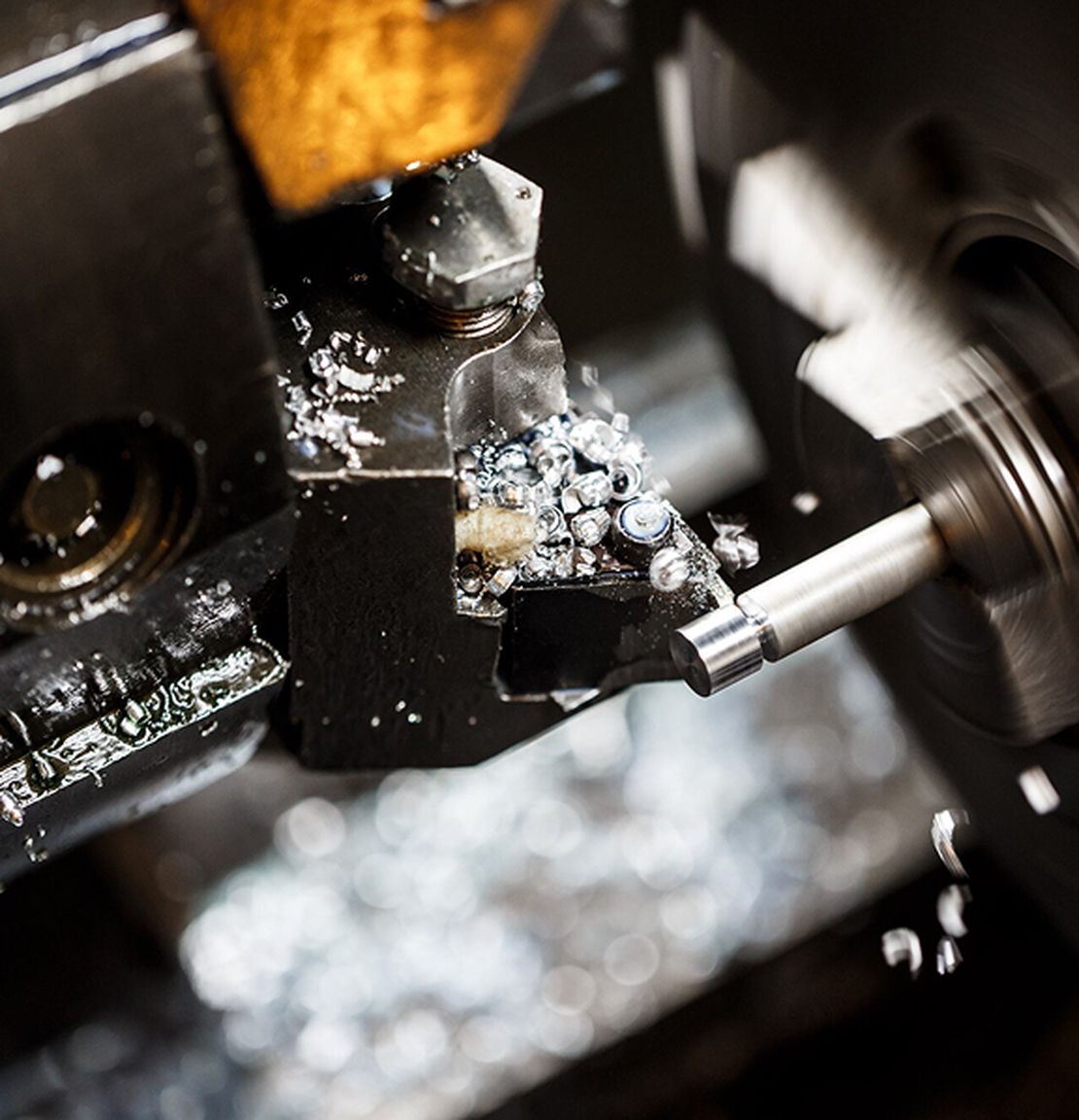

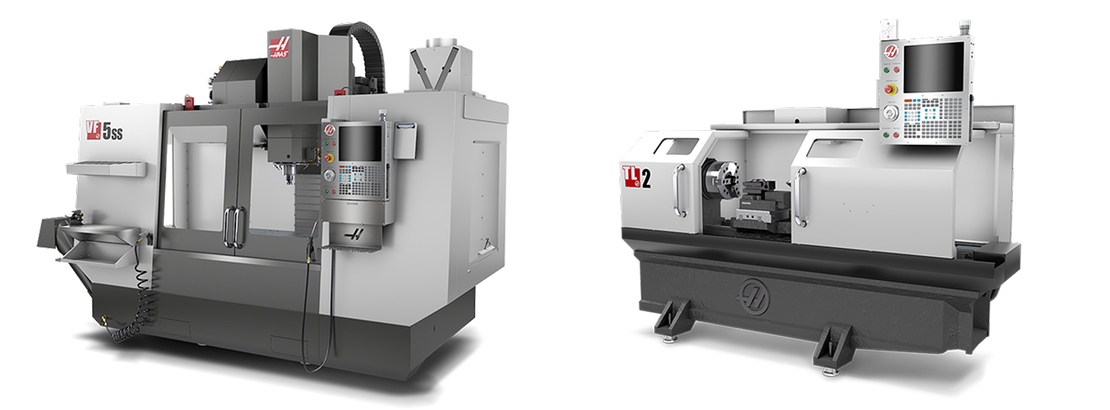

Manufacturing and Machining

Our tooling is manufactured using state-of-the-art CNC machines, ensuring maximum precision and consistency. We operate high-performance CNC lathes and milling machines, including HAAS equipment, capable of processing components up to 1250x750x550 mm (milling) and 1200x290 mm (turning). This guarantees exceptional surface quality, minimal dimensional tolerances, and optimal accuracy, contributing to the longevity and reliability of the tooling.

All components undergo strict quality control, including dimensional verification using coordinate measuring machines (CMM) and functional tests on specialized test benches.

FAQ

FAQ

Testing and Implementation

After manufacturing, we conduct functional and assembly tests in our facility to verify the proper operation of all components. This includes checking assembly tolerances, mounting forces, operating pressures, and other key parameters. Additionally, we perform durability and performance tests to evaluate how the tooling functions under real production conditions.

Service and Support

Upon project completion, we provide comprehensive service and warranty support, including operator training, maintenance, and tooling upgrades. If necessary, we can implement design modifications or deliver additional accessories and tools to accommodate evolving production needs.

Through close collaboration with our clients and meticulous attention to detail, Accuma delivers tooling that not only meets strict quality standards but also enhances production efficiency, reduces downtime, and optimizes operational costs.

Formularz kontaktowy

Zadzwoń